Corn is America’s top agricultural crop, and also one of its most wasteful. About half the harvest—stalks, leaves, husks, and cobs— remains as waste after the kernels have been stripped from the cobs. These leftovers, known as corn stover, have few commercial or industrial uses aside from burning. A new paper by engineers at UC Riverside describes an energy-efficient way to put corn stover back into the economy by transforming it into activated carbon for use in water treatment.

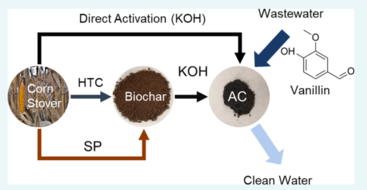

An illustration depicting how corn stover is turned to biochar, then to activated carbon for water filtration. (Abdul-Aziz et. al., 2021)

Activated carbon, also called activated charcoal, is charred biological material that has been treated to create millions of microscopic pores that increase how much the material can absorb. It has many industrial uses, the most common of which is for filtering pollutants out of drinking water.

Kandis Leslie Abdul-Aziz, an assistant professor of chemical and environmental engineering at UC Riverside’s Marlan and Rosemary Bourns College of Engineering, runs a lab devoted to putting pernicious waste products such as plastic and plant waste known as biomass back into the economy by upcycling them into valuable commodities.

“I believe that as engineers we should take the lead in creating approaches that convert waste into high-value materials, fuels and chemicals, which will create new value streams and eliminate the environmental harm that comes from today’s take-make-dispose model,” Abdul-Aziz said.

Abdul-Aziz, along with doctoral students Mark Gale and Tu Nguyen, and former UC Riverside student Marissa Moreno at Riverside City College, compared methods for producing activated carbon from charred corn stover and found that processing the biomass with hot compressed water, a process known as hydrothermal carbonization, produced activated carbon that absorbed 98% of the water pollutant vanillin.

Hydrothermal carbonization created a biochar with higher surface area and larger pores when compared to slow pyrolysis- a process where corn stover is charred at increasing temperatures over a long period of time. When the researchers filtered water into which vanillin had been added through the activated carbon, its combination of larger surface area and bigger pores enabled the carbon to absorb more vanillin.

“Finding applications for idle resources such as corn stover is imperative to combat climate change. This research adds value to the biomass industry which can further reduce our reliance on fossil fuels,” Gale said.

The paper, “Physiochemical properties of biochar and activated carbon from biomass residue: influence of process conditions to adsorbent properties,” is published in ACS Omega.